We were anxious to see the progress that has been made in cleaning up the historic environmental impacts in the Copper Basin. Glenn Springs Holdings, LLC is the Occidental Petroleum (OXY) subsidiary that is managing the work in the North Potato Creek watershed where most of the mining and milling took place. CLICK HERE for an area map. OXY inherited the cleanup responsibility as a result of its acquisition of Cities Service Petroleum which had purchased the Tennessee Chemical Corporation (previously the Tennessee Copper Corporation (TCC)) in 1983. The metallurgical and chemical plant sites in the vicinity of Copperhill are mainly in the adjacent Davis Creek watershed. Copperhill Industries is conducting the environmental cleanup in that area. Because our time was limited and the Copper Basin is so large, we were only able to visit a few of the project sites which are currently inaccessible to the public. Special thanks to Glenn Springs Holdings Project Manager, Scott Deal, for guiding us around. In addition to facility removal and remediation at mining and milling sites, much work has involved reclamation of tailings impoundments, construction of water treatment plants, rerouting streams, prevention of acid rock drainage, and continuing revegetation. We got to see many examples of the completed cleanup actions as we explored the area. As the photos below illustrate, the progress is impressive. |

Glenn Springs Holdings’ Copper Basin Project Office in a repurposed bank building in downtown Ducktown. | |

The Burra Burra Mine, the London Mine, and the East Tennessee Mine were located along the northwestern limb of the Burra Anticline. We passed the capped and reclaimed McPherson Shaft of the Burra Burra (Above) on the way to the London Mill site. CLICK HERE for an historic view if the McPherson Shaft site. (J.J. Patton photo, ca1927-1930, Georgia Mineral Society).

|

The London Mill started production as a copper concentrator in 1922. In 1926 and 1927, additional flotation circuits were added to produce iron and zinc concentrates respectively. By the 1960s, it processed 4,700 tons per day from several Copper Basin mines and was the largest sulfide concentrate producer in the U. S. CLICK HERE for a diagram of the mill flowsheet. Mill tailings were disposed in a large impoundment. (Lewis and Morris, 1962)

| |

All that remains of the London Mill is the foundation that once supported the ore bins that received the ore from the TCC mines. The ore from the bins was blended to provide a consistent blend that fed the grinding and flotation circuits. The mill was demolished and the site has been reclaimed. CLICK HERE for a view of the mill ruins before reclamation. (EPA)

|

| |

(Left) An evocative view under the ore bins of the London Mill. (Right) The area adjacent to the mill that once held conveyors, thickeners, shops, a warehouse, and the mill office has been recontoured, capped, and revegetated. Drainage channels route clean water to uncontaminated waterways. |

|

Acid producing rock and other solid wastes have been removed from dumps, settling ponds, and creeks near the London Mill. Wetlands have been created in their place. | |

The immense tailings ponds associated with the London Mill have been either revegetated or form freshwater wetlands and lakes. They now provide habitat for many species of animals and birds.

|

The historic Ocoee Mine was a small, early operation that was later dwarfed by the nearby TCC East Tennessee Mine. The ruins of ore bins can be seen in the forest if you know where to look. | |

Foundations of milling equipment are nearly hidden in the undergrowth. It was the first flotation mill in the Copper Basin. Thanks to our guide, Scott, we were able to visit this remote site.

|

| |

The Central Headframe (Left) and Hoist House (Above) are the last ones remaining in the Copper Basin. They were constructed in 1950. The shaft provided ore hoisting for the Boyd Mine and Calloway Mine. Ore trains transferred the ore to the London Mill. CLICK HERE for a photo of an ore train loading at the Central Shaft. (Tennessee State Library and Archives) The Central Shaft and Hoist are located close to highway between Ducktown and Copperhill. They have been remediated by Glenn Springs and hopefully will become part of the Ducktown Basin Museum and the historic site at some time in the future.

|

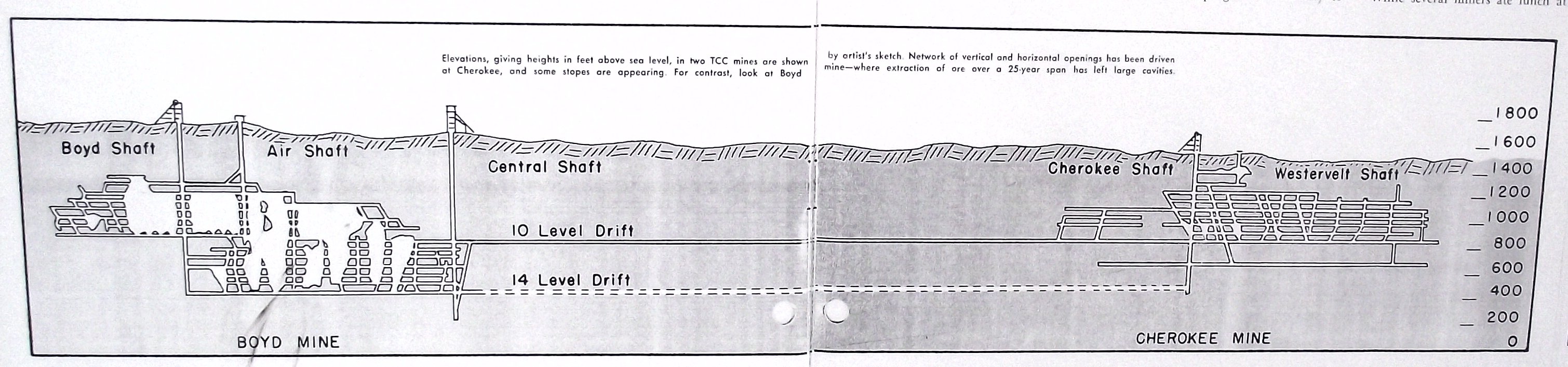

The Central Shaft served as an ore hoisting shaft for both the Boyd Mine and Cherokee Mine. Trains loaded ore from the bin and transported it to the mill. (Ducktown Basin Museum exhibit)

|

(Above) The operator’s control room was located behind the hoist drums. (Right) A close-up view of the operator’s control console. He received signals from underground telling him what action was needed to raise or lower the skips and cages in the shaft. The gauges in the center of the console show their location in the shaft.

| |

|

A view of the front of the hoist drums. | |

The Hoist House also contained the Miner’s Dry. Remediation work has exposed the wall studs of the locker room but the lockers remain.

|

Although time constraints did not allow us to visit the Copperhill, Tennessee plant sites, the photos below show the extent and complexity of the historic complex and some of the environmental remediation challenges they posed. CLICK HERE for maps of the plant areas with changes made over its years of operation (USACE, EPA, SAIC, 2008). The historic photos below are from the same source. More recent information about the environmental cleanup can be found on the Copperhill Industries website.

|

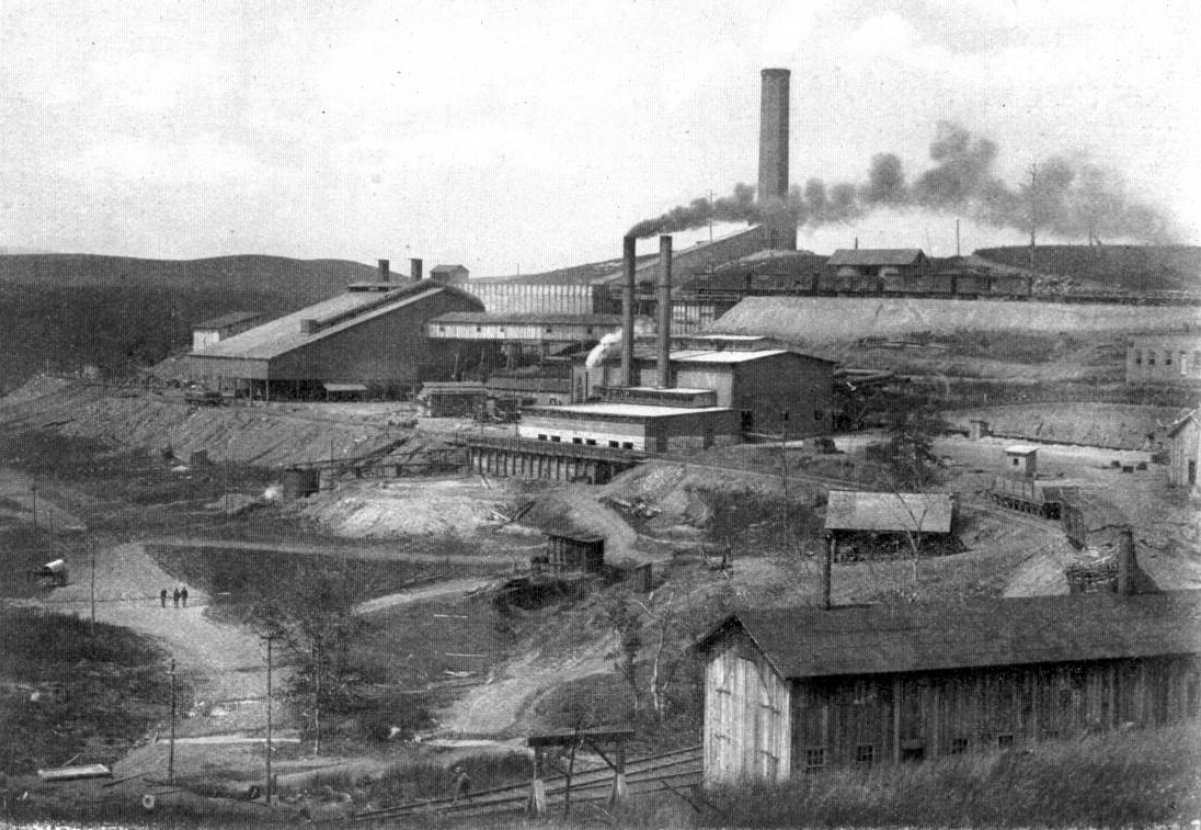

View of the original TCC Copper Smelter in operation (1902). The large stack and flue are from the two smelter furnaces and convertors. The power plant is at the center.

| |

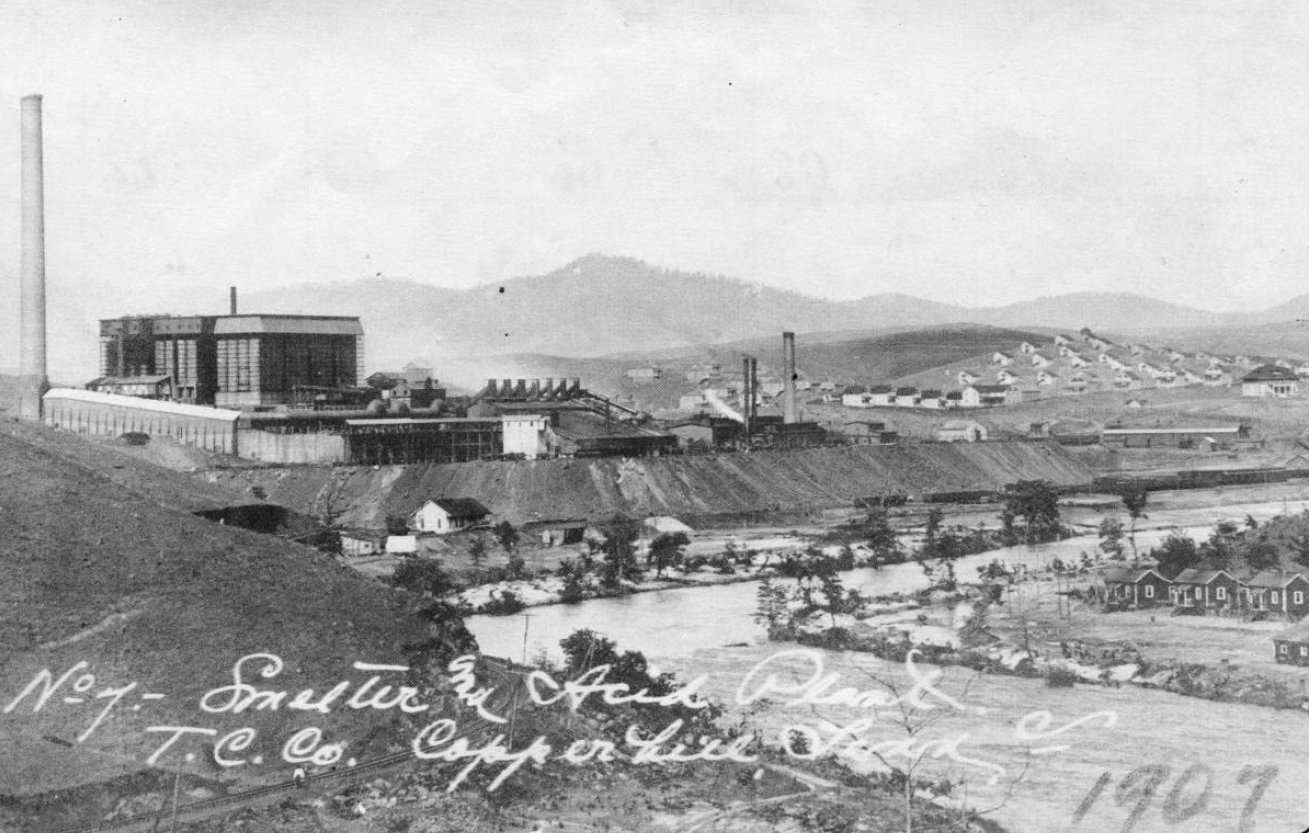

View of the newly constructed Acid Plant No. 1 (1907). The Ocoee River is in the right foreground. The copper smelter, now expanded to 7 furnaces, is behind the acid plant. |

|

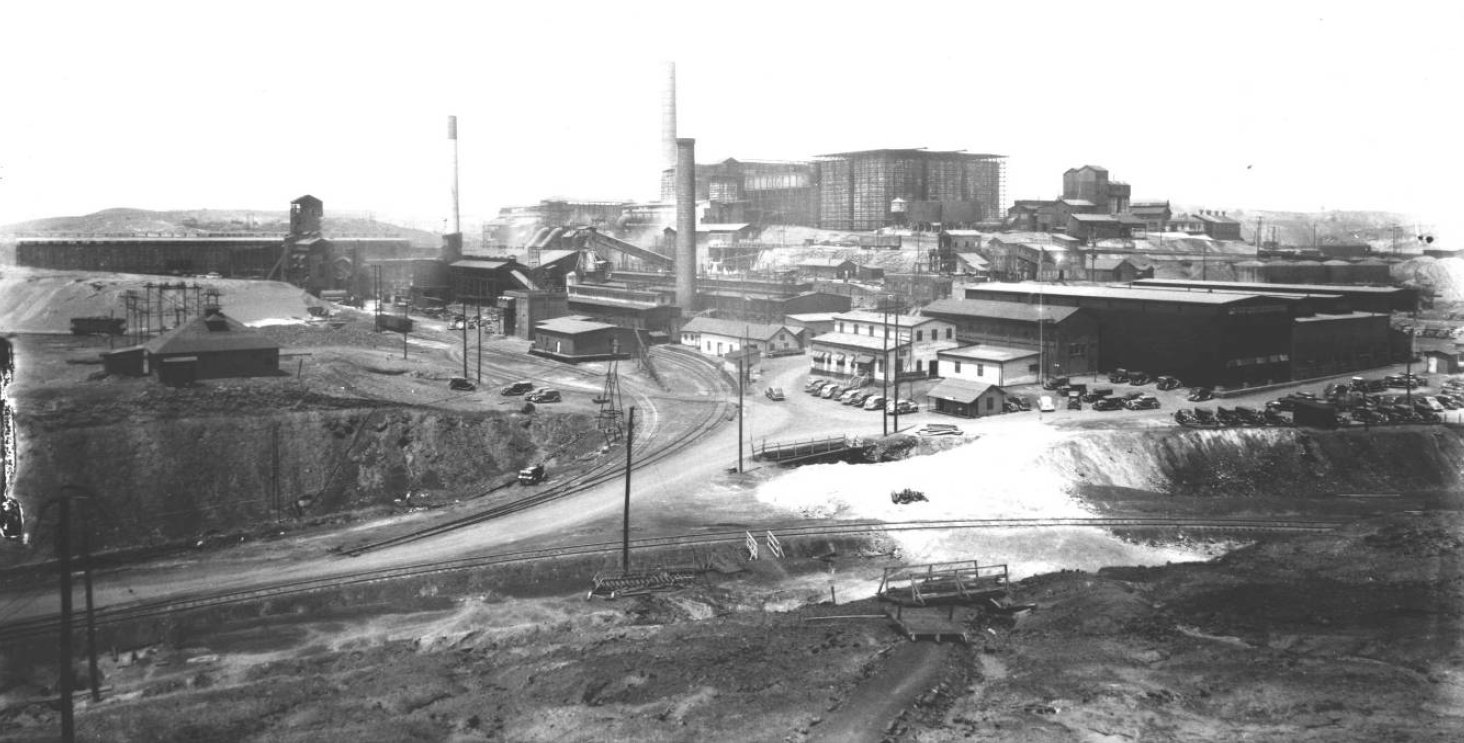

View of the greatly expanded Copperhill Plants (1940). The World War II era was a boom period for TCC metals and chemical production.

|

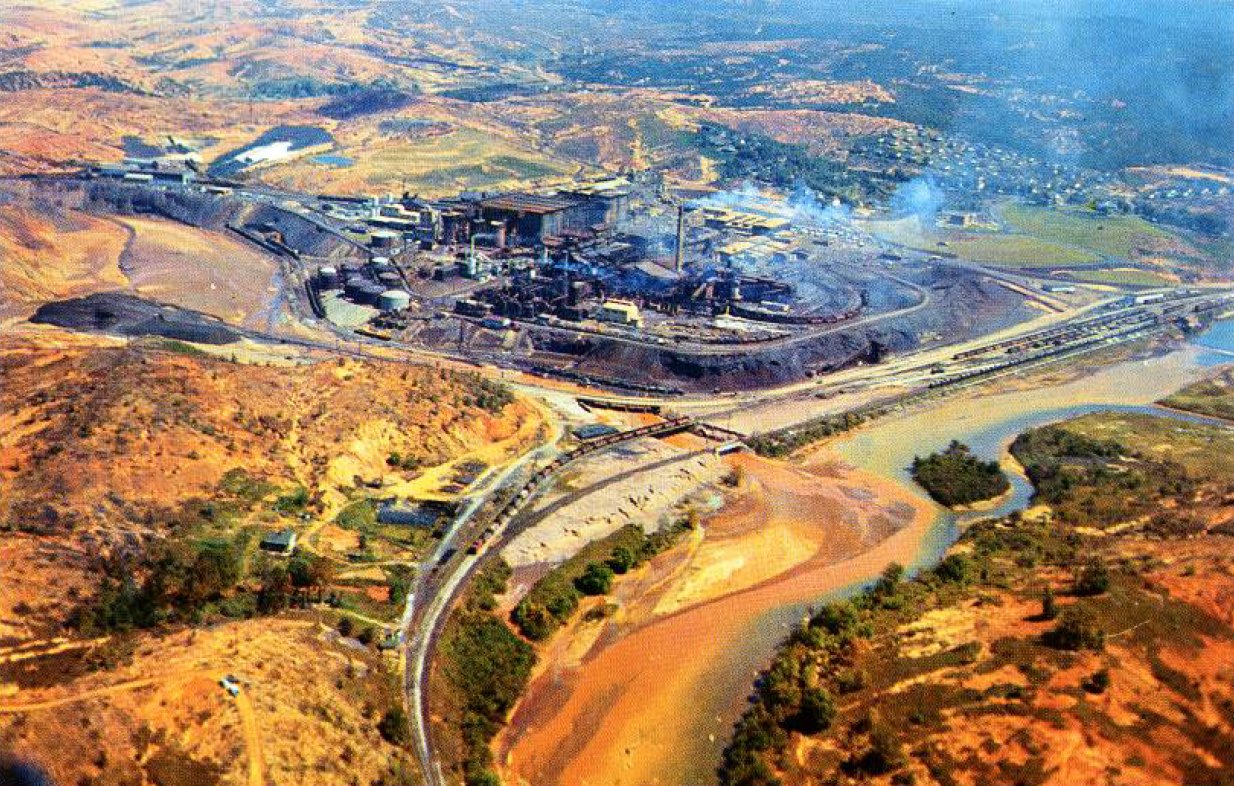

Aerial view of the Copperhill Plant complex of copper smelting, iron sintering (iron ore pellets after 1972), chemical manufacturing, and acid plants (1957). The environmental effects are seen in the surrounding hills and along Davis Mill Creek where it forms a delta before entering the Ocoee River. | |

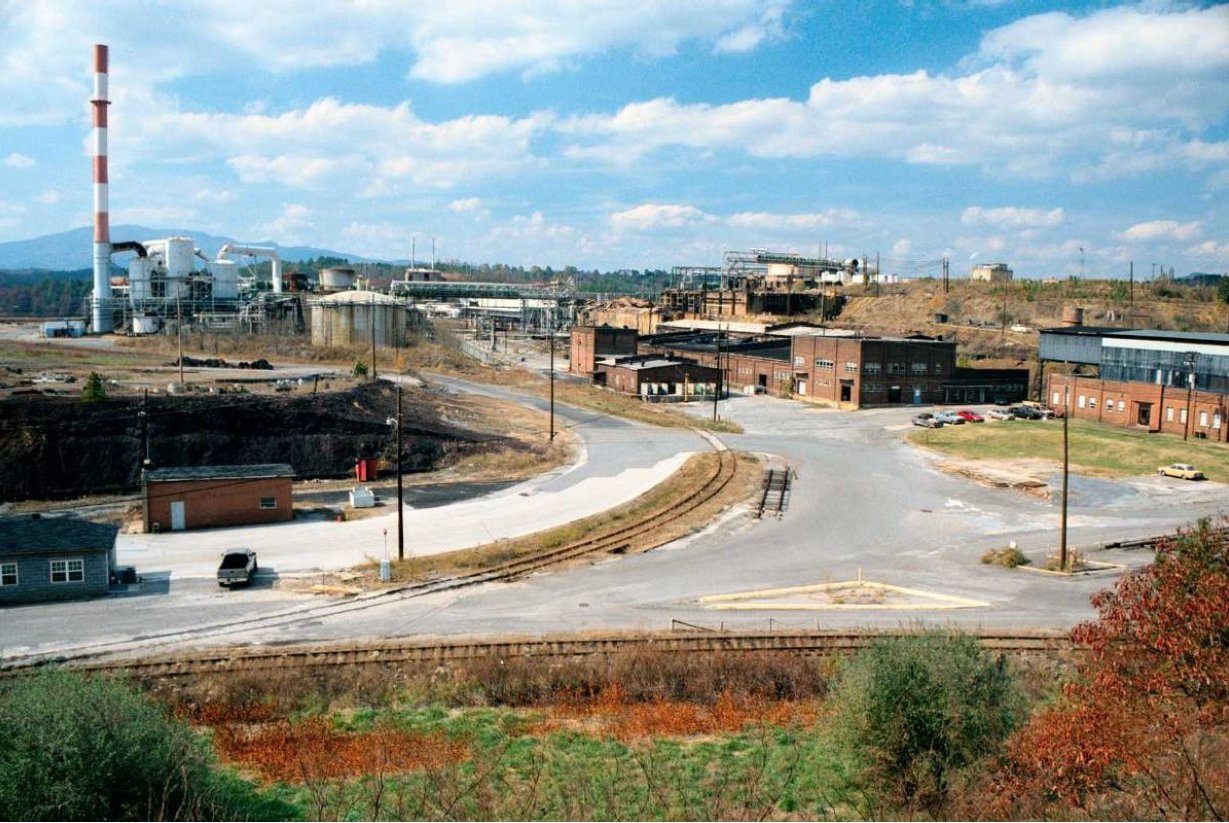

View of the Copperhill Plant complex (2001). Acid Plant No. 6 is at the left. It has since been removed. Only the foundations of the early acid plants remain on the top of the hill. The ruins of the smelter are on the side of the hill.

|

This trip report would not be complete without mentioning our brief “drive through” visit to Cleveland, Tennessee. Sadly, and in spite of inquiries, we were unable to find any trace of the copper refinery and rolling mill that had operated briefly during the early years of the Civil War. We did, however, have a pleasant surprise. We found Julius Raht’s home still standing in a semi-industrialized neighborhood near the railroad tracks. Raht used the building as an office for his company and as a residence when he visited the area. His company manager lived in another house still standing next door. At the time of our visit Raht’s house was for sale. Is anyone interested in buying an historic home?

|

Front view of Julius Eckhardt Raht’s home/office in Cleveland, Tennessee. | |

Side view of Raht’s house with additions added after his time.

|

Now it was onward to the 2022 Mining History Association Conference in Birmingham, Alabama! There are several more photo galleries from field trips taken during the Birmingham Conference. Just click on the conference link at the bottom of this page. Thanks for touring with us virtually.

|