|

|

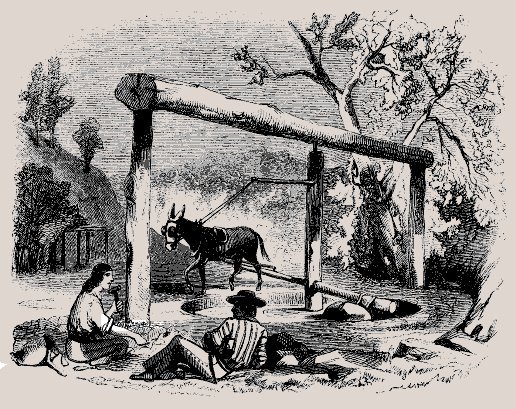

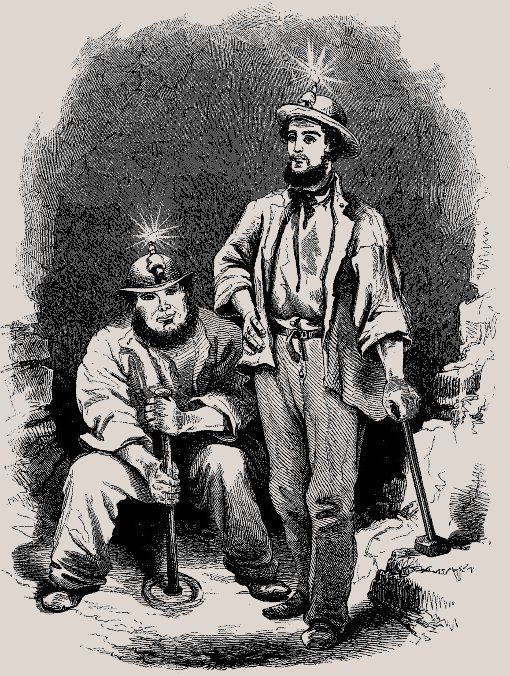

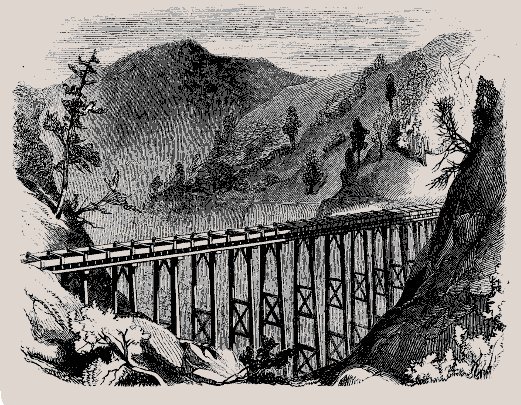

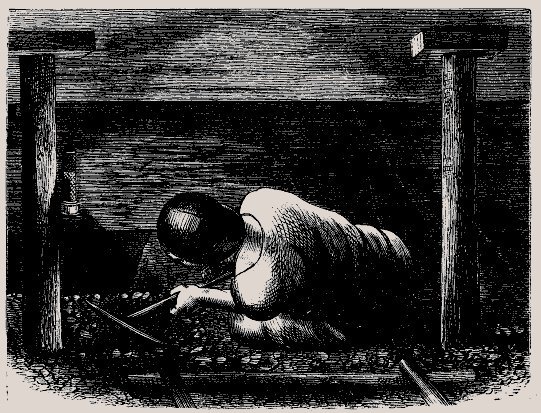

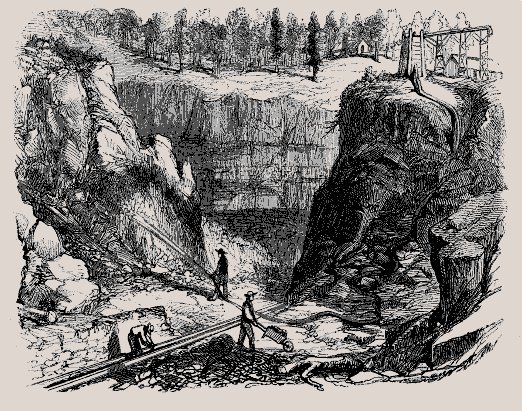

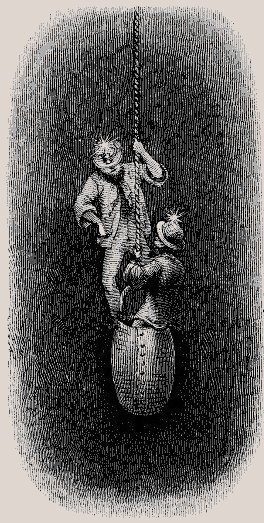

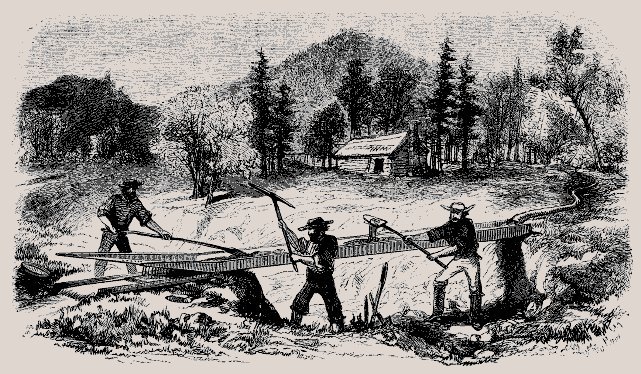

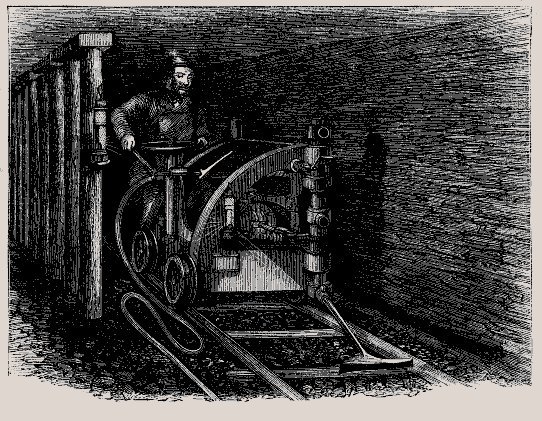

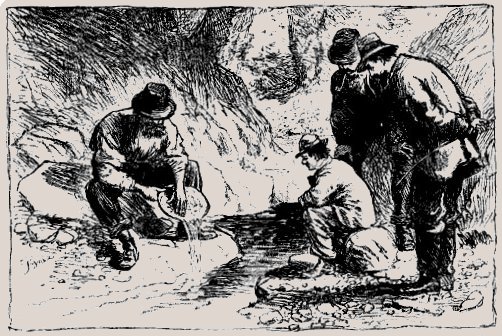

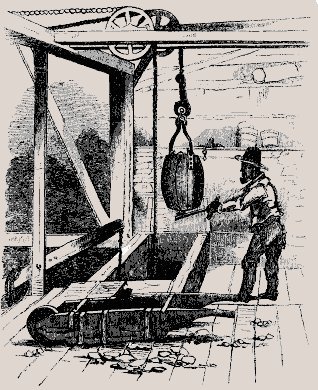

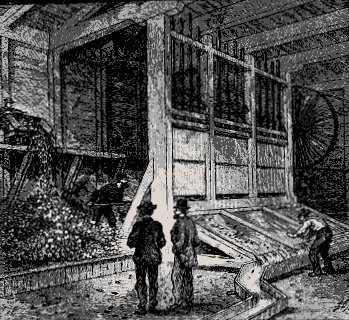

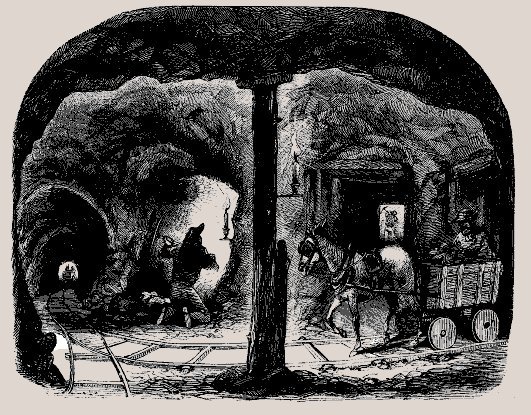

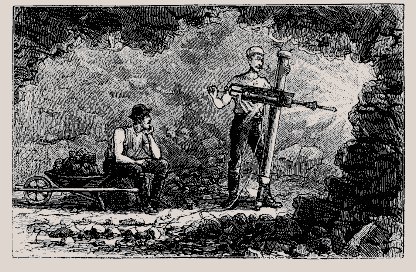

Mining History Resources Mining Glossary QUICK OVERVIEW OF SOME BASIC MINING TERMS  A B C D E F G H I J K L M N O P Q R S T U V W X Y Z  A Adit. A horizontal tunnel from surface to access an ore body. Aerial survey. An exploration survey made from an aircraft with photographic equipment and/or remote sensors that measure magnetism or radioactivity. Aerial tramway. A system for transporting ore or rock in buckets that are suspended from cables. Agglomeration. Sticking together of small mineral particles to form clusters or balls, usually in preparation for sintering or pelletizing. A clay binder may be used to hold the particles together. Alluvial, Alluvium. Deposits of sedimentary material such as sand, gravel, and silt, laid down in river beds, flood plains, lakes, or at the foot of mountain slopes. The waste material in placer mining. Amalgam. Alloy of mercury with another metal such as gold or silver. Amalgamation. Process by which gold and silver are extracted from finely crushed ore by passing them over a surface coated with mercury. The metals and mercury form an amalgam which is periodically scraped from the surface. The precious metals are then recovered by distillation of the mercury. AN/FO. Ammonium nitrate and fuel oil explosive. Anode, Copper anode. The positive side of the electrolytic cell. An anode is a rectangular plate of copper (or other metal) cast in a shape suitable for refining by an electrolytic process. Anomaly. Term applied to departure from normal or field characteristic, commonly used in geophysical prospecting for minerals. For example, in a magnetometer survey, an area showing much higher (or much lower) magnetic intensity than surrounding area would be identified as an anomaly. The anomaly might be considered a target for further exploration on the ground. Apex. Top or terminal edge of vein on the surface or its nearest point to surface. Apex Law. The law giving the owner of a claim containing the top of a vein the right to mine down the dip of the vein beyond the sidelines of the claim. Arrastra, Arrastre. A simple, primitive rock lined pit in which large stones attached to a horizontal wooden bar are dragged in a circular motion to crush and grind ore. Powered by a horse or mule walking in a circular path. Ash. The inorganic portion of a coal seam with little or no energy value. Ash is removed in coal cleaning processes. Assay. To test ores or minerals by chemical or other methods to determine amount of valuable metals contained. Assessment work. Amount of work specified by law that must be done each year to retain legal control of an unpatented mining claim. Auger, Auger mining. Removal of coal under a highwall by drilling adjacent large diameter horizontal holes into the coal with an auger. Autogenous grinding, Semi-autogenous grinding (SAG). Process of grinding ore in a rotating mill that uses large pieces of the ore being ground as the grinding medium instead of conventional steel balls or rods. Grinding balls are added in semi-autogenous grinding (SAG) mills. Top of the List B Back. Roof of tunnel or working chamber in a hardrock mine. Backfill. Material such as waste rock or mill tailings used to fill a mined out stope to prevent its collapse after mining. Ball mill. Piece of milling equipment used to grind ore into small particles. Crushed ore is fed into a cylindrical-shaped steel container filled with steel balls. As the mill is rotated, the balls cascade, grinding the ore. Base metal. Metal inferior in value to gold and silver, generally applied to commercial metals such as copper, zinc, and lead. Bedrock. Solid rock forming earth's crust, frequently covered by soil, overburden, or water. Belt conveyor. A continuously moving endless strip of rubber supported on rollers used to transport crushed material. Bench. Mining level or cut in an open pit mine. Beneficiation, Beneficiate. To concentrate or enrich ore. Generally applied to the preparation of ore before smelting. Includes such processes as crushing, grinding, washing, flotation, and magnetic separation. Biological leaching. Process for recovering metals from low-grade ores by dissolving them in a solution. The dissolution is aided by bacterial action. Bit. The cutting tool of a boring device. In rock drilling, the bit is frequently made with ultra-hard material such as tungsten carbide or diamonds. Black powder. An early type of mining explosive containing potassium nitrate, charcoal, and sulfur. Blast, Blasting. The ignition of explosives to break solid rock in a mine. Blasting Cap. A detonator used to ignite explosives. A length of fuse is attached to the cap to provide time for the miners to reach a safe place before the explosion. Modern blasting caps are electrically ignited. Blasting pattern. The layout of a series of blast holes to provide optimum breakage. Blast hole. Hole drilled for purposes of blasting rather than for exploration or geological information. Blast hole drill. A percussion or rotary drill used to create a series of holes for explosives in surface mining. Blister copper. Product of the Bessemer-type converter furnace used in copper smelting. An impure form of copper metal assaying about 99% copper. It requires further refining before being used for industrial purposes. Block caving. Low cost method of mining in which large blocks of ore are undercut, leaving the ore to break and cave under its own weight. Blockholing. Breaking undesirable large rocks in a pit or quarry by drilling short holes into them and blasting them with explosives. Bonanza. Very rich ore deposit producing at a profit. Borrasca. A worthless mine or mineral deposit yielding no profit. Box cut. The initial excavation to start a new, deeper level of an open pit mine. Breaker. A processing plant in which anthracite coal is crushed and sorted by size. Coal washing or cleaning may also be done. Breaker boy. Young boy who picks slate from coal in a breaker. Child labor laws outlawed this practice. Breast. Working face where mining is taking place in a dipping coal seam or vein. Buck, Bucking. Breaking ore manually using a broad headed hammer. Bucket. A wooden or steel container for hoisting ore. Also see Kibble. Bucket conveyor, Bucket elevator. A continuous series of buckets attached by pivots to chains driven by sprockets. Typically used to raise material to a higher elevation. Buddle. A device for gravity separation of ore minerals from waste material. A slurry of pulverized ore flows down an inclined plane or cone, causing the heavier ore particles settle out faster then the lighter particles of waste. Periodically, the different sections of separated minerals are removed for further processing or disposal. Bulk sample. Large ore sample, frequently involving many tons, selected to be representative of material being sampled. May be used to obtain an accurate assay or to test potential processing techniques. Burden. Rock between an open bank and line of blast holes. Bureau of Mines, USBM. The U. S. Bureau of Mines (USBM) was the minerals arm of the U. S. government from 1910 until it was closed in 1996. It conducted research on mining, metallurgy, health and safety, minerals conservation, and environmental control. Worldwide mineral statistics were collected and published annually (publication continues by the U. S. Geological Survey). Mineral resource studies were conducted on Federal lands. Technical analysis and support was provided for government decision making. By-product. Secondary or additional metal or mineral product recovered from an ore. Top of the List  Two Cousin Jack miners in a North Carolina gold mine C Cage. Conveyance used to transport men, ore cars and equipment, and supplies in shaft. Cager. The miner who directs the movement of the cage in the mine shaft. Candle. A rod of wax with a wick used to provide light underground. Cap lamp. A battery powered lamp worn on a miner’s hardhat. Carbide lamp. A miner’s lamp in which calcium carbide and water are used to generate acetylene gas which is ignited to provide illumination underground. Carbon-in-leach (CIL). A pulp of pulverized gold ore is leached in tanks containing a cyanide solution. The gold in the solution is simultaneously adsorbed on activated carbon from which it is then recovered. Carbon-in-pulp (CIP). A pulp of pulverized gold ore is leached in tanks containing a cyanide solution. After the leaching process, the gold is then adsorbed on activated carbon from which it is then recovered. Car, Mine car. A wheeled vehicle used to transport coal or ore. Casing. Pipe placed in drill hole to keep it from caving in. Cathode. Rectangular sheet of pure metal that forms the negative side of an electrolytic cell. Metal ions from the impure anode plate onto the cathode. The refined metal on the cathodes is then melted into commercial shapes such as wirebars, billets, ingots, etc. Valuable byproducts are recovered from the sludge at the bottom of the cell. Cement copper. Copper recovered from solution in ground water, leachate, or mine drainage by precipitating on scrap iron. Chamber. Enlarged portion of blast hole to make room for a larger explosive charge. Change house. Special building at a mine where miners change into working clothes before going underground. Also known as a "dry house" or “dry” because damp work clothes dry out between shifts. Channel sample. Sample composed of pieces of ore that have been cut out of a small trench or channel about four inches wide and an inch or so deep. By taking channel samples at regular and close intervals, accurate estimate of grade of a deposit can be obtained. Chilean mill. A coarse grinding machine in which rollers crush the ore against a circular iron base. Churn drill. Drill whose head is lifted by rope and dropped successively to make the hole. Chute. An inclined opening usually constructed of timber and equipped with a gate, through which ore is drawn from a stope into mine cars. Claim. Under Federal and local laws, a portion of mining land held by an individual or group by virtue of discovery, location, and recordation. Mining laws and regulations define the size and shape of a claim. For example, lode claims are typically 600 feet by 1500 feet. Annual assessment work is required until full ownership is obtained through patent. Clarifier. Large tank used for cleaning water or solutions of foreign matter by settling. Chemical flocculents may be added to speed settling. Classifier. Device in which particles of mixed size and weight are sorted by settling through liquid or air. Spiral and cyclone classifiers are common types. Cleaning, Coal cleaning. Separating clean coal from waste rock in a preparation plant or breaker. Closed circuit. Loop in a process wherein a selected portion of product of a machine is returned to head of machine for finishing to required specifications. Commonly used examples in milling plants include grinding mills in closed circuit with classifiers. Cobbing, Hand cobbing. Breaking ore with hammers to sort valuable pieces from waste rock. Collar. Term applied to the timbering or concrete around top of a shaft. Also used to describe top of drill hole. Comminution. The crushing and grinding stages of ore dressing. Complex ore. Ore containing a number of minerals of economic value, usually implying difficult metallurgy to extract them. Compressor, Compressed air. Machine for compressing air to a pressure sufficient to actuate mining equipment and machinery. Concentrate. Product containing valuable mineral(s) or metal(s) from which most waste material in ore has been eliminated. The concentrate must then be treated in some other type of plant such as smelter to effect final recovery of the mineral(s) or metal(s). Concentrator. A beneficiation plant that produces a concentrate of valuable mineral(s) or metal(s). Cone crusher. Machine in which rock is broken by the pinching action between a central rotating cone and a stationary shell. Contact. Line along which two different types of rocks come together. Continuous mining, Continuous miner. A high productivity method of mining coal with a mobile mining machine that combines the functions of breaking coal from the face (without drilling and blasting) and loading it into a shuttle car or onto a conveyor in a single continuous operation. Once the coal is loaded from one face the continuous miner can move to other faces while roof support and ventilation are extended into the previously mined area. Conventional mining. Mining coal with sequential non-automated methods. The typical cycle of operations is cut and/or drill and blast, load, haul, and dump plus setting timber or installing roof bolts for support and directing air flow for ventilation. Converter. In copper smelting, a Bessemer-type furnace used to reduce copper metal from matte and to slag off the iron impurities. Also used in steelmaking. Conveyor. A machine used to transport material. See belt conveyor. Core. Long cylinder of rock, about one inch or more in diameter, which is cut by diamond drill. Used to evaluate geologic structure and assay for mineral content. Core barrel. The tool in the hole during diamond drilling in which a core specimen collects. Country rock. The general mass of non-mineralized rock adjacent to ore body, as distinguished from the mineralized vein or ore deposit itself. Cousin Jack. An immigrant miner from Cornwall, England. In the 1800’s, Cornish miners were instrumental in spreading mining knowledge to the Americas, Australia, and elsewhere. Cousin Jennie. The Cornish wife of a Cousin Jack. Crosscut. Connecting tunnel between drifts in a hardrock mine or entries in a coal mine. Crusher. Machine for crushing rock by mechanical force, such as in a gyratory crusher, jaw crusher, cone crusher, or roll crusher. May be used in a primary, secondary, and tertiary series to crush material to continuously smaller sizes. Cut and fill. A method of stoping in which ore is removed in slices or lifts, following which the excavation is filled with rock or other waste material known as backfill before the subsequent slice is mined. Backfill supports walls of a stope. Cutting. A slot is made in a coal face by hand pick or cutting machine. The slot provides an additional surface to which the coal can break. Cyanidation. Method of extracting gold or silver by dissolving it in a weak solution of sodium cyanide. Cyclone classifier, Cyclone. Conical shaped device that uses centrifugal force for separating mineral particles by size. Also used for removing water and slimes. Top of the List  Double-jacking at the face of a North Carolina gold mine. D Decant. Controlled overflow of water or solutions from processing vessels. Development. Underground work carried out for reaching and opening up a mineral deposit. Includes shaft sinking, crosscutting, drifting, and raising. Diamond drill. Rotary type of rock drill in which cutting is done by abrasion using a diamond studded bit attached to the end of long hollow rods through which water is pumped to cutting surface. The drill cuts a core of rock, which is recovered in long cylindrical sections, an inch or more in diameter. Core samples are used to study geology and perform assays. Differential flotation. Milling using the flotation process in stages by which concentrates are made of each of various valuable minerals in ore. Dilution. Waste or low-grade rock unavoidably removed along with ore in mining process. Dip. Angle at which vein, structure, or rock bed is inclined from horizontal, measured at right angles to strike. Dip needle. Compass whose needle is mounted to swing in vertical plane. Used for determining magnetic attraction of rocks. Disseminated ore. Ore carrying small particles of valuable minerals spread more or less uniformly through waste material. Distinct from massive ore, wherein valuable minerals occur in almost solid form with little waste material included. Double jack, Double jacking. Two-pound sledge hammer. Takes name from hand drilling by a pair of miners, one to swing the hammer and the other to hold the drill steel. Down-the-hole drill. A percussion drill in which the bit driven mechanism enters and follows down the drill hole as it is deepened. Also see rotary drill and percussion drill. Dragline. Long-boomed surface mine excavator with bucket that is filled by dropping and dragging by cable toward machine. Dredge. A floating extraction plant that excavates and processes unconsolidated placer deposits to recover valuable metals. Commonly used for gold and tin. Dressing, Mineral dressing, Ore dressing. Milling and concentration of ores. Drift, Drive. Horizontal passage underground that follows along length of vein or rock formation, as opposed to crosscut, which crosses through the vein or formation. Drifter. Rock drill used for boring horizontal holes for blasting. Drill, Drilling. A device for cutting a circular hole in rock or ore. Drill steel. Steel rods with bits used to drill holes into rock and ore. Drum hoist. Mine hoist in which conveyances such as cages and skips are suspended on cables wound onto individual drums. In shafts with two or more compartments, skips can be counter-balanced. Dry house. Building where miner changes into and out of working clothes. Also known as "change house". Damp work clothes dry out between shifts Dump. A pile or heap of rock or ore on surface. It may contain waste rock or low grade ore to be leached. Also the act of unloading a mine car or truck. Dynamite. A nitroglycerine based explosive ignited with a blasting cap. Top of the List E Eimco loader, Rocker shovel. A loading machine using a front-mounted scoop that is pushed into a pile of broken material and then throws the material backward into a trailing mine car. Named for Eimco, the manufacturer. Electrolytic refining. Process of refining impure metals. The impure metal is cast into anodes, which are placed in electrolyte solution. An electric current allows metal ions to pass through the solution, depositing the pure metal on a cathode. Commonly used in copper and zinc production. Electrostatic separation. Sorting of mineral particles by using their differential movement in response to electrical field. Elutriation. Measurement of the speed at which particles fall freely in fluid. Important in process of thickening by decantation. Engine, Beam engine, Cornish engine. A steam driven engine used to operate pumps or hoists in a mine shaft. Entry. Horizontal opening or tunnel in a coal mine. ERTS. Earth Resources Technology Satellite (ERTS) used to collect data useful in mineral exploration. Also called LANDSAT. Exploration. Prospecting and other work involved in searching for ore, coal, and minerals. Explosives. Chemical substances used to break rock in mining. See black powder, dynamite, and AN/FO. Extractive metallurgy. Recovery of metals from their ores by physical/mechanical and/or chemical methods. Includes mineral dressing, pyrometallurgy, hydrometallurgy, and electrometallurgy. Top of the List  Flume bringing water to a California placer mine. F Face. Mine opening in which work is progressing, as applied to a drift, crosscut, or stope. Fan, Ventilation fan. Used to circulate air in a mine or to exhaust contaminated air from the mine. Feeder. Mechanical device, usually automatic, for controlling the supply of ore or coal to a processing machine such as a crusher. Also applies to the controlled dispensing of reagents in processes. Fire assay. A method assaying metallic ores, usually gold and silver, by heating the crushed ore sample in a crucible in a furnace to cause the waste material to form a slag and separate from the metal. The recovered metal is weighed to determine the grade of the ore. Flotation. Milling process by which some mineral particles agitated in a solution of water and chemicals to become attached to bubbles and to float to the surface, while other particles sink. In this way, valuable minerals are concentrated and separated from each other or from worthless gangue. Flocculant. A chemical added to mineral slurries to speed the settling out of solids by forming clusters or lumps of particles. Flowsheet. Diagram showing sequence of step-by-step operations by which ore or coal is processed. Flume. An open wooden channel supported by trestles for conveying water from a distant source to a placer mine. Flux. Substances such as limestone and silica, used in metallurgical furnaces to react with gangue minerals to form slag which is liquid at high temperatures. The slag floats on the molten metal or matte and can be drawn off separately from the metal. Fools gold. Pyrite, iron sulfide. Its brassy yellow color causes it to be mistaken for gold. Footwall. Barren rock on the underside of vein or ore structure. Free milling. Milling of ores of gold or silver from which precious metals can be recovered by concentration methods without roasting or chemical treatment. Friction hoist. Mine hoist in which conveyances are suspended on cables from both sides of a simple friction pulley, which imparts the desired motion. Distinct from drum hoist, in which ropes are wound onto individual drums. Front end loader. A mobile loading machine with a bucket in front. The bucket is pushed into a pile of broken material. Once loaded, the bucket can be raised and the machine can maneuver into position to dump the material into a haul truck or rail car. Frue vanner. See Vanner. Fuse. A length of slow burning explosive cord used to ignite a blast. It is used to provide time for the miners to reach a safe place before the explosion. Also see Blasting cap. Top of the List  Pick and shovel mining at a coal face. G Gamma. Unit of measurement of magnetic intensity. Gangue. Worthless minerals associated with the valuable minerals in ore deposit. Geiger counter. Instrument used in search for radioactive minerals, particularly uranium. Contains a Geiger-Muller tube which detects and measures radioactivity. Geology. The science that deals with the structure and history of the earth as recorded in rocks. Geochemistry, Geochemical survey. The study of the abundance of chemical elements in the various parts of the earth, e.g. the earth’s crust. In a geochemical survey systematic samples are collected and analyzed. Data patterns are studied for anomalies that may indicate the presence of an ore deposit. Geophysics, Geophysical survey. Scientific method of prospecting that utilizes physical properties of minerals to detect their presence. Common properties investigated include magnetism, specific gravity, electrical conductivity, and radioactivity. Glory hole. Funnel-shaped opening from the surface to the underground workings. Ore is excavated from sides of funnel and dropped to the workings below where it is then drawn off underground and transferred to a shaft or adit. Gob. Caved areas left behind once the coal has been removed. Grab sample. Sample taken at random and assayed to determine whether valuable elements are contained in rock. Grab samples are not usually considered to be representative of the true grade of a deposit. Grade. The percentage of metal in ore. Also a measure of the slope of haulage roads or track. Gravimeter, Gravity meter. Instrument for measuring gravitational attraction of earth, which varies with density of rocks in vicinity. Gravity separation. Separation of mineral particles by difference in specific gravity. Jigs, buddles, tables, vanners, and spiral classifiers are common gravity separation machines. Grizzly. Grid of rails or bars to prevent oversize material from entering an ore pass. Larger pieces are broken so they can pass through the grizzly. Gross value. Theoretical value of ore in ground, determined simply by applying the assay of metal or metals and current market price. Grouting. The process of sealing off water flow in rocks by forcing a thin cement slurry or other materials into crevices. Usually done through drill holes. Grubstake. Money or supplies furnished by an investor to a prospector on promise of some share in any discoveries he makes. Guides. Timber along sides of shaft for steadying or guiding a cage or skip. Gyratory crusher. Machine in which rock is broken by pinching action between a gyrating center core and a stationary shell. Top of the List  Hydraulic mining in the California gold fields. H Hand loading. Using a shovel to manually load a mine car. Hanging wall. Barren rock on upper side or topside of vein or ore deposit. Hardrock, Hardrock mining. Mining minerals other than coal. Haulage. Transporting broken ore, coal, or waste. Haul road. Surface mine roads used by mobile equipment for the transport of ore or waste. Headframe. Tower over top of a shaft that permits lifting ore buckets or skips to the surface. Hearth, Hearth furnace. A small furnace or the part of a larger furnace in which sufficient heat is produced to melt metallic ore. An air blast may be used to increase the heat at the hearth. Heavy-liquid separation. Process in which liquid of high specific gravity separates minerals from waste by their difference in specific gravity. See heavy media separation. Heavy-media separation. Process in which a suspension of minerals in water acts as fluid that separates valuable particles from waste. In coal processing, the heavy-media is usually a slurry of water and magnetite iron particles in which the coal floats and the waste rock sinks Highwall. The wall of rock left after stripping has stopped in a coal surface mine. Highwall mining. Mining coal under a highwall using specially designed extraction equipment. See auger mining. High grade, High grading. Rich ore. Also a term applied to the selective mining of only the best ore in a deposit. Hoist. Machine used for raising and lowering a cage or skip in shaft. Hydraulic mining, Hydraulicking. A placer mining method in which high pressure water jets are used to loosen gravels so that gold can be recovered from them. Hydraulic shovel. A loading shovel powered by hydraulics rather than cables, drums, and pulleys. Hydrometallurgy. Separation of metal in aqueous solution from rest of ore, followed by precipitation in metallic form. Top of the List I Incline, Ramp, Spiral ramp, Decline. An inclined excavation for opening and servicing an underground mine. Used by mobile equipment to transport men and materials. A steeply dipping shaft is also called an incline. Induced polarization. Method of ground geophysical surveying employing electrical current to determine indications of sulfide mineralization. Industrial minerals. Usually nonmetallic minerals which are used in industrial and manufacturing processes in their natural state, though with some beneficiation to imposed specifications. Examples include asbestos, salt, gravels, building materials, talc, sand, etc. Ion exchange. Exchange of ions in crystals with ions in solution. Used as method for recovering valuable metals in solution; for example, uranium. Top of the List J Jackleg. Air-pressure-operated piston that supports a light rock drill. Jaw crusher. Machine in which rock is broken by action of moving steel jaws. Jet piercing. Method of making blast holes in iron formations. Combustion of kerosene and oxygen makes hot flame that spalls rock. Jig. A gravity separation apparatus used to concentrate ore. Pulverized ore is placed on a screen submerged in a container of water. Either by reciprocating motion of screen or by pulsation of water through it, the heavier mineral particles settle to the bottom and lighter gangue particles migrate to the top. Periodically, the different sections of separated minerals are removed for disposal or further processing. Jumbo, Drilling jumbo. A mobile drilling carriage machine containing 1 or more drills. Top of the List  Miners riding the kibble in a shaft. K Kibble. A steel bucket used for hoisting ore in an open mine shaft. Koepe hoist. (See "friction hoist".) Top of the List  Long Tom being used for recovering California placer gold. L Ladder shaft. A shaft used by the miners to enter and leave the mine by climbing a ladder. Lagging. Planks or small timbers placed along roof and/or sides of a drift to prevent rocks from falling into it. Lagging is frequently used between timbers that support main weight of overlying rocks. Lamp, Miner’s lamp. A means of illumination for the miner’s underground workplace. Typical lamps used oil, carbide, and electricity to provide light. Also see Cap lamp and Carbide lamp. LANDSAT. Earth satellite used for collection of data useful in mineral exploration. Also called ERTS. Launder. Chute or trough for conveying a slurry of ore and water in a milling process, or waste tailings to a disposal pond. Leachate. The solution containing minerals extracted by leaching. Leaching. The process by which the valuable minerals in mine dumps or piles of low grade ore are dissolved. The leachate typically is pumped to a recovery plant where the mineral values separated from solution. Typically used to recover copper and gold. Also, chemical process used in milling for extraction of valuable minerals from ore and the natural process by which ground water dissolves minerals. Ledge. A bed or zone of ore. Sometimes used to refer to a mineralized zone of gold bearing quartz. Level. Horizontal passages on a working horizon in mine. It is customary to develop levels at regular intervals down a shaft, generally 100 to 150 feet or more apart. LHD. A rubber tired mining machine that combines the functions of loading, hauling, and dumping ore or waste in an underground mine. Line cutting. Straight line cleared through bush to permit sights to be taken for geophysical and other surveys. Litharge. An oxide of lead. Load, loading. The act of placing broken ore or waste rock in a mine car or truck. Loader, Gathering arm loader. A machine that loads broken coal or similar material by using oscillating mechanical arms to pull the material onto a conveyor that places it in a shuttle car. Lode. Mineral bearing vein or deposit in solid rock. Long Tom. A long trough for washing stream placer material to recover gold. Long ton. 2240 pounds. Longwall mining. Method of completely mining a large block of a coal seam. Hydraulic supports provide temporary support at the face while a cutter removes the coal which is conveyed out of the mine. As the cutter and support move through the block, the roof is allowed to cave behind the supports. Top of the List  Early longwall coal mining face. M Magnetic separation. Process in which a magnetically susceptible mineral is separated from gangue minerals by applying strong magnetic field. Taconite iron ores are commonly treated this way. Magnetometer. Sensitive instrument used to measure magnetic attraction of underlying rocks. Marginal ore deposits. Ore bodies approaching lowest limits of commercial workability. Matrix. Rock or gangue material containing ore minerals. Matte. Product of a smelter, consisting of metal with some contained impurities. It must be further refined to obtain pure metal. Metallurgy. Various methods of preparing metals for use by separating them from their ores. Metallurgical technologies are frequently divided into extractive metallurgy (beneficiation), hydrometallurgy (recovering metals from solutions), pyrometallurgy (recovering metals by using heat), etc. Mill. A beneficiation plant in which hardrock ore is treated for recovery of valuable metals or minerals. Concentrates from a mill may be shipped to a smelter or other type of plant for further processing. Also, a machine consisting of a revolving drum for fine-grinding of ores in preparation for further treatment. See rod mill, ball mill, and pebble mill. Mill heads. Average grade of ore fed into a mill. Milling. Same as grinding. Loosely used to mean beneficiation. Milling ore. Ore that contains sufficient valuable mineral to be treated by milling process. Mine. An opening or excavation in the earth for extracting minerals. Mineral. Naturally occurring inorganic substance having definite physical properties and chemical composition and, if formed under favorable conditions, a definite crystal form. Model, Mine model. A physical, three-dimensional, small scale representation of an orebody and/or mine workings. Models are constructed to enable visualization of the geology and mine workings. They are often used in litigation. Modern computer methods have largely replaced the need for physical models. Monitor, Hydraulic giant. A hydraulic, placer mining device used to create a jet of water that is directed on the face to break apart the alluvium. Motor, Mine motor. An electrically or compressed air-powered locomotive to haul cars in an underground mine. Muck. Ore or rock broken by blasting. Muck stick. A hand shovel. Top of the List N Native metal. Metal that occurs in nature pure or uncombined with other substances. Native gold and copper deposits were sought by early prospectors and miners. Top of the List O Open cut, open pit. Surface working, open to daylight. Open stoping. Mining method in which ore is extracted from an underground chamber. Pillars of rock or ore may be left in placed to provide support. Ore. Mixture of metals or minerals and waste material/gangue from which at least one of the metals or minerals can be extracted at a profit. Orebody, Ore body. A solid and fairly continuous mass of ore which may include low-grade ore and waste material. Ore dressing. Treatment of ore to remove waste materials. See “beneficiation.” Ore house, Rock house. A building near the shaft in which ore is sorted from waste rock before it is sent for further processing. Ore pass. A near vertical opening for dropping ore to a loading point on a lower level or at the shaft. Ore reserves. The principal assets of a mine as to measured tonnage and grade. They may be classified as proven, probable, or possible, in decreasing degree of accuracy and statistical confidence based on sampling. To combat fraud, many nations have developed standards by which ore reserves are to be calculated and reported. Outcrop. Exposure of rock or mineral deposit that can be seen on the surface. Overburden. The material covering an orebody or coal deposit. It must be removed before surface mining can begin. Oxidation. Chemical processes usually affecting near-surface ore that results in change in the mineralogy and/or composition of the ore by taking on more oxygen. Top of the List  Panning for gold in Georgia gold rush. P Pan, Panning. A shallow dish-shaped container used to separate precious metals from in gravel. By swirling the material in the pan the metal particles settle to the bottom. A basic tool for early prospectors to rapidly assess the presence of gold in a stream. Used by individual miners to recover placer gold. Patent, Patented claim. A document conveying title of a tract of ground (e.g. a mining claim) and signifying that no further assessment work is required. Patio process. A process of recovering silver by amalgamation. Pay dirt. Gravel containing sufficient precious metals such as gold to make mining profitable. Pebble mill. A cylindrical shaped grinding mill, similar in construction and action to ball mill, but in which charge is made up of hard pebbles in place of more conventional steel balls. Pellet, Pelletizing. Marble-sized ball of iron mineral bonded by clay material and fused in a furnace for hardness. Percussion drill. A device for drilling a hole in rock by a bit repeatedly striking the rock surface. A piston delivers blows to the shank of the steel rod on which the bit is mounted. Pillar. Block of solid ore or rock left in place for supporting walls or roof in mine. Placer. Alluvial deposit of sand and gravel containing valuable minerals such as gold and tin. Porphyry copper. Deposit of disseminated copper minerals in large body of porphyry rock. Portal. Surface entrance to tunnel or adit. Preparation plant, Coal preparation. A plant that removes waste from coal or ore. Prospect. Mining property whose value has not been proved by exploration. Pulp. Pulverized or ground ore in a water-based slurry. Pump. A device to remove water from a mine opening. Pyrometallurgy. Processes for recovering metals from mineral concentrates by using heat, such as in smelting. Top of the List Q Quarry. A surface mine in which building stones and/or construction materials are produced. Quarrying for construction aggregates may use drilling, blasting, loading, and haulage methods typical of metal and coal mining. To avoid fracturing building stone, entire blocks of material are freed by drilling and wedging or cutting before being hoisted out of the quarry by cranes. Top of the List  Gold rocker in the California Gold Rush. R Radioactivity. Property of spontaneously emitting alpha, beta, or gamma rays by disintegration of nuclei of atoms. Raise. Vertical or inclined underground workings excavated from the bottom upward. Reagents. Chemicals used in metallurgical processes, particularly flotation and SX/EW chemicals. Ream, reaming. Enlarging a hole by redrilling with a special bit. Reclaim, Reclamation. Restore a previously mined area by regrading the surface and seeding or planting vegetation. Reconnaissance. Preliminary examination survey of ground. Recovery. Percentage of valuable metal in ore that is recovered by metallurgical treatment. Reduction, Reduction works. Extraction of metal from ore in a milling and smelting plant(s). Refractory ore. Ore that is difficult to treat. Reserve. (See Ore reserves.) Resistivity survey. Geophysical technique in which resistances presented to an electrical current by various members of a structure are measured. Resource. A prospective area of mineralization but with insufficient definition and sampling to be considered part of an ore reserve. The resource may be near or adjacent to an area of defined ore reserves. Revegetation. Seeding and or planting a previously mined area. (See Reclamation.) Reverberatory furnace. Long flat furnace used in smelting concentrates. The principal function is slagging of gangue minerals and production of matte. Rib. Side wall in tunnel or working place. Used in coal mining. Roasting. Treatment of ore by heat and air, or oxygen-enriched air, to remove sulfur and/or arsenic prior to further treatment. Rocker. Hand operated device for recovering gold from stream gravels. Rock burst. Sudden failure of walls or pillars in mine caused by weight or pressure of surrounding rocks and accompanied by violent release of energy. Rod mill. Rotating cylindrical mill that employs steel rods as grinding medium. Roll crusher. Machine in which rock is broken by pinching action of two moving steel rolls. Roof bolt, Rock bolt. Steel rod used to support rock in mine workings. The bolt is placed in a drill hole. A wedge, expansion shell, or epoxy cement hold the bolt in position. Pressure on an external bearing plate helps support the rock. A geometric pattern of bolts can support a large area. Room and pillar. Method of mining flat-lying deposits in which the roof or back of the mined area is supported by pillars of coal or ore left in place. Also see stope and pillar. Rotary drill. A type of drill in which a bit attached to a steel rod is rotated against the rock. In a rotary percussion drill, a hammering action is combined with the rotation of the bit. Royalty. Amount paid by lessee or operator to owner of a mine or mineral deposit. Generally based on certain amount per ton or percentage of total production or profits. Run-of-mine. Ore or coal as it comes from the mine before processing. Top of the List  The ore bucket arrives at the mine shaft collar. S St. Barbara. Patron saint of miners, artillerymen, and those that work with explosives. Salt, Salting. Introducing particles of metal or mineral into a prospect, deposit, or samples, thus making assays run higher than they actually should. Done either accidentally or with intent to defraud. Sample. To select a fractional but representative part of a deposit for analysis. Scaling. Act of removing loose pieces of rock from the back/roofs and/or walls/ribs. Scintillation counter. Instrument used for detecting and measuring radioactivity by detecting gamma rays. More sensitive than Geiger counter. Seismic prospecting. Geophysical method of prospecting utilizing knowledge of speed and reflection of sound waves in rock. Selective flotation. (See Differential flotation.) Self-potential. In geophysical prospecting, technique that recognizes and measures minute electrical currents generated by sulfide ore bodies. Shaft. Vertical or inclined excavation for opening and servicing a mine. Usually equipped with hoist at the top, which lowers and raises conveyances for handling men and material. Shaking conveyor, Pan conveyor. A conveying device composed of a series of metal troughs that is given a reciprocating action to move material. The movement is composed of a slow forward stroke and a rapid backward stroke. Most commonly used in coal mining. Sheave wheel. Large grooved wheel placed in top of the headframe and over which the hoisting cable passes. Shovel, Power shovel. A device used for loading material. May be hand operated to load mine cars. Also may be a mechanical device for loading trucks in a surface mine. Short ton. 2000 pounds. Shrink stoping, Shrinkage stoping. Mining method in which miners work standing on broken ore and excavate upward. Sufficient broken ore is removed after each blast to permit miners to enter. When all the ore has been broken, the entire stope is emptied and may be backfilled. Shuttle car. A rubber tired vehicle used to transfer coal or ore from a loading area at the mining face to a conveyor or train for transport from the mine. Single jack. A hammer used in hand drilling by a single miner who holds the hammer in one hand and the drill steel in the other. Sintering. Making concentrate into a solid mass by heating without melting. Also reduces sulfur. Sizing. Separating ore particles by size, typically by screens after crushing. Skip. The conveyance that runs on guides in a shaft and is used for hoisting ore or rock. Slag. Vitreous mass separated from fused metals in smelting process. Slope. An inclined mine passage from the surface to the workings or between different levels of the workings. Slope stability. Degree to which the walls of a surface mine maintain a stable grade or angle when exposed to elements. Sluice, Sluice box. In placer mining, an inclined trough or box used for gravity separation of gold particles from gravel. Also see Long Tom. Sludge. Mixture of drill cuttings and water from drill holes. Used for sampling ore grade or for stemming blast holes. Slurry explosive. A viscous explosive typically used in surface mines to completely fill the contour of the drill holes. Frequently used when holes contain water. The explosive is sometimes packaged in plastic bags. Slusher. Two-or three-drum winch dragging scraper bucket on continuous cable to move broken rock or ore. Spelter. Zinc metal. Spiral classifier. Gravity separation device in which ground ore in water is passed through vertical spiral troughs. Square set, Square-set stoping. Mining method in which weak ground is supported by a rectangular or square timber frame or set as soon as ore is extracted. Each frame is supported on those below and to sides. The miners work inside the frame as they drill and blast the next cut of ore. Stamp mill, Stamp battery. A crushing machine with a mortar and pestle action. Iron stamp heads or shoes are repeatedly dropped on pieces of ore which rest on iron dies in the mortar box. Multiple stamps were assembled in a stamp battery. The finely crushed ore proceeds to the next stage of processing. Early stamp mills used water or steam power. Station. Enlargement of a shaft made at a level. Used primarily for storage and handling of equipment and materials near the shaft. Stemming. Material such as drill cuttings used to confine explosives in drill hole. Stockpile. Broken ore accumulated in heap on the surface, pending treatment or shipment. Stope, Stoping. An underground chamber from which ore is extracted. Stope and pillar. Method of mining flat-lying or shallow-dipping hardrock deposits in which the roof or back of mined area is supported by pillars of rock or ore left in place. Also see Room and pillar. Stoper. A lightweight percussion-type drill used for upward drilling in a stope. Strike. Direction or bearing of a vein or rock formation measured on a level surface. Strip. To remove the overburden or barren rock overlying a coal seam or ore body. Strip mine. A surface coal mine in which waste overburden is removed before coal extraction. Sublevel. Intermediate level or working horizon in mine opened between main working levels. Sump. Excavation underground for catching or storing water before pumping to the surface. Bottom of a shaft is commonly used for this purpose. SX/EW. Solvent Extraction/Electro Winning is a process by which metal is extracted from a leachate and then passed in solution to electrolytic cells for recovery of the pure metal. In copper mining SX/EW has made recovery of low grade ore possible and has eliminated the need for smelting. Top of the List  Stamp mill in a Georgia gold mill. T Table, Shaking table, Wilfley table. A gravity separation device that employs a reciprocating, nearly flat surface (table) with riffles. A slurry of pulverized ore flows across the table while the surface reciprocates back and forth. The lighter weight particles are propelled toward the end of the table while the heavier mineral particles settle out and move toward the side of the table where they are recovered. The Wilfley table was named for its inventor. Tailings. Material rejected from mill after recoverable valuable minerals have been extracted. Tailings pond, Tailings dam. Disposal area for mill tailings. Thickener. Large round tank for separation of solids from solution. Clear liquid overflows tank, whereas rock particles sink to bottom. Used to thicken tailings before released to a disposal pond. Tipple. The structure on the surface in which mine cars are dumped. Commonly used in coal mining when the coal from the mine is dumped into bins for eventual loading into trains. Toe. Base of a level or bench in a surface mine. Also used to describe the burden of rock between bottom of blast hole and free face. Train, Mine train. Locomotive and cars used to haul ore or waste in a mine. Trench. Long, narrow excavation dug through overburden, or blasted out of rock, to expose a vein or ore structure. Used for exploration and sampling. Tripper. A mechanical device for continuously discharging and distributing ore from belt conveyor into line of bins or stockpile. Truck, Haul truck. Vehicle for transporting broken ore, coal, or waste material in a surface mine. Tunnel. A horizontal underground passage open to atmosphere at both ends. Loosely applied in many cases to an adit, in hard rock mining, or an entry, in coal mining. Top of the List  Scene in an underground gold mine in California. U Underground, Underground mine, Lode mine. A mine below the surface of the ground. Uranium. An energy mineral used in reactors in nuclear power plants. Top of the List V Vanner, Frue vanner. An ore concentrating device in which the slurry of fine ore flows down a slightly dipping continuous belt. The belt vibrates from side to side. The heavier minerals migrate to one side of the belt and can be recovered. Vein. Fissure, fault, or crack in rock filled by ore and other minerals that have traveled upward from a source located deep in the earth. Ventilation. Providing fresh air to underground mine workings and exhausting contaminated air. May be natural means (e.g. warm air rising, cold air sinking) or by fans. Top of the List W Wagon drill. A drill mounted on movable carriage. Usually employs long drill steel, thus not requiring frequent changes. Wall rock. The rock forming the walls or sides of a vein or ore deposit. Also referred to as country rock. Washing, Washer, Washery. Cleaning impurities from ore or coal by agitation in a vessel or device usually containing water. Waste. Barren rock or uneconomic mineralized rock in mine. Wedging. Placing of wedge at some point in hole to deflect the bit in another direction, as in diamond drilling. Also, in quarrying building stones, wedges are placed in a line of short holes to split out large pieces of stone. Whim, Horse whim. A hoisting apparatus in a mine shaft. The vertical capstan on which rope is wound may be driven by animals. Windlass. A hand cranked device for lowering or hoisting things in a mine shaft. Winze. Shaft connecting underground levels excavated downward. Opposed to a raise. Top of the List  Early percussion drilling in a hardrock mine. X X-ray analysis, X-ray fluorescence. The use of x-ray instrumentation to identify minerals, analyze the grade of ore. Also used in instrumentation to control milling and flotation circuits. Top of the List Y Yellow cake. Uranium concentrate. Top of the List Z Zone, Ore zone. Area or region that is distinct from surrounding rock either because of difference in type or structure of rocks or because of mineralization. Top of the List CONTACT US if you would like to add a new term or suggest a modified definition. (Illustrations courtesy Harpers Weekly, ca1800s) |