The Copper Queen Mine Tour enjoyed by the MHAers is still interpreting this historic mine. Visitors to museums around the world marvel at the spectacular copper mineral specimens that came from the Copper Queen Mine. |

Commemorative plaque at the Copper Queen Mine extols The Importance of Copper Mining. |

Visitors suit up with hard hats and miners’ lamps before heading underground. |  The mine train takes visitors to an underground stope where the mining process is explained and the copper ore can still be seen. The mine train takes visitors to an underground stope where the mining process is explained and the copper ore can still be seen.

|

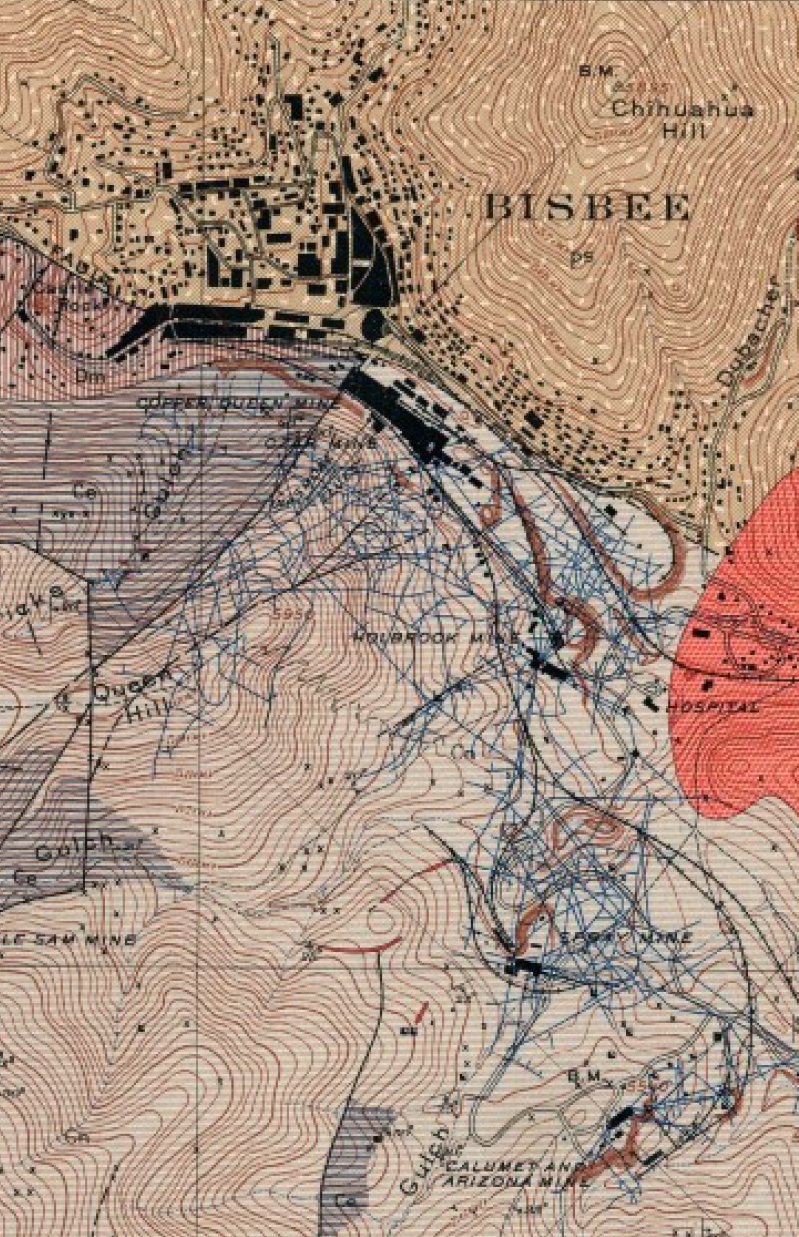

(Above) The Copper Queen orebody was discovered because it was exposed in the hillside across from downtown Bisbee. Mining began at the surface in the “Glory Hole” and then followed the ore deep underground. (Right) Miners eventually developed a maze of horizontal tunnels in several mines (the blue lines on the 1904 US Geological Survey geologic map). Vertical shafts and underground raises connected the horizontal levels to extract the ore. The Copper Queen Mine and the Queen Mine Tour are located in the uppermost part of the mine workings. |  |

The mine train passes the Queen Inclined Shaft. The shaft station is being restored in 2020 using 12” x 12” timbers in an interlocking square set pattern. |

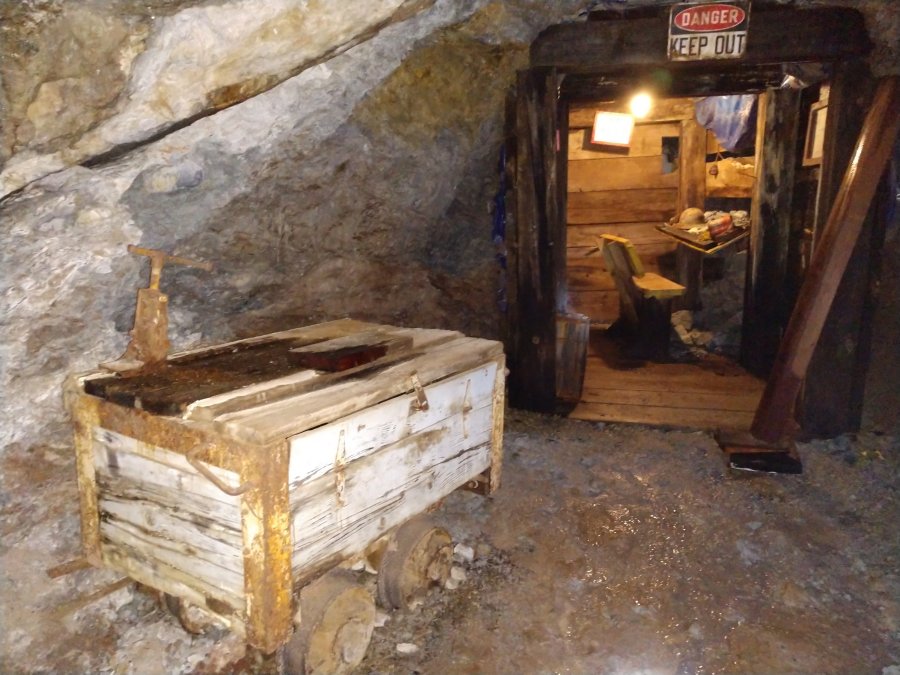

Along the entrance drift the mine Foreman’s underground office in a short side tunnel. |

initially, hand drilling was used by the miners to make holes for explosives. Compressed air drills, shown above, were introduced later to increase drilling speeds and reduce costs. |

The ore was mined above the levels in openings called stopes. The broken ore was dropped down chutes to ore cars waiting on the level. The loaded cars were then taken to a shaft. |

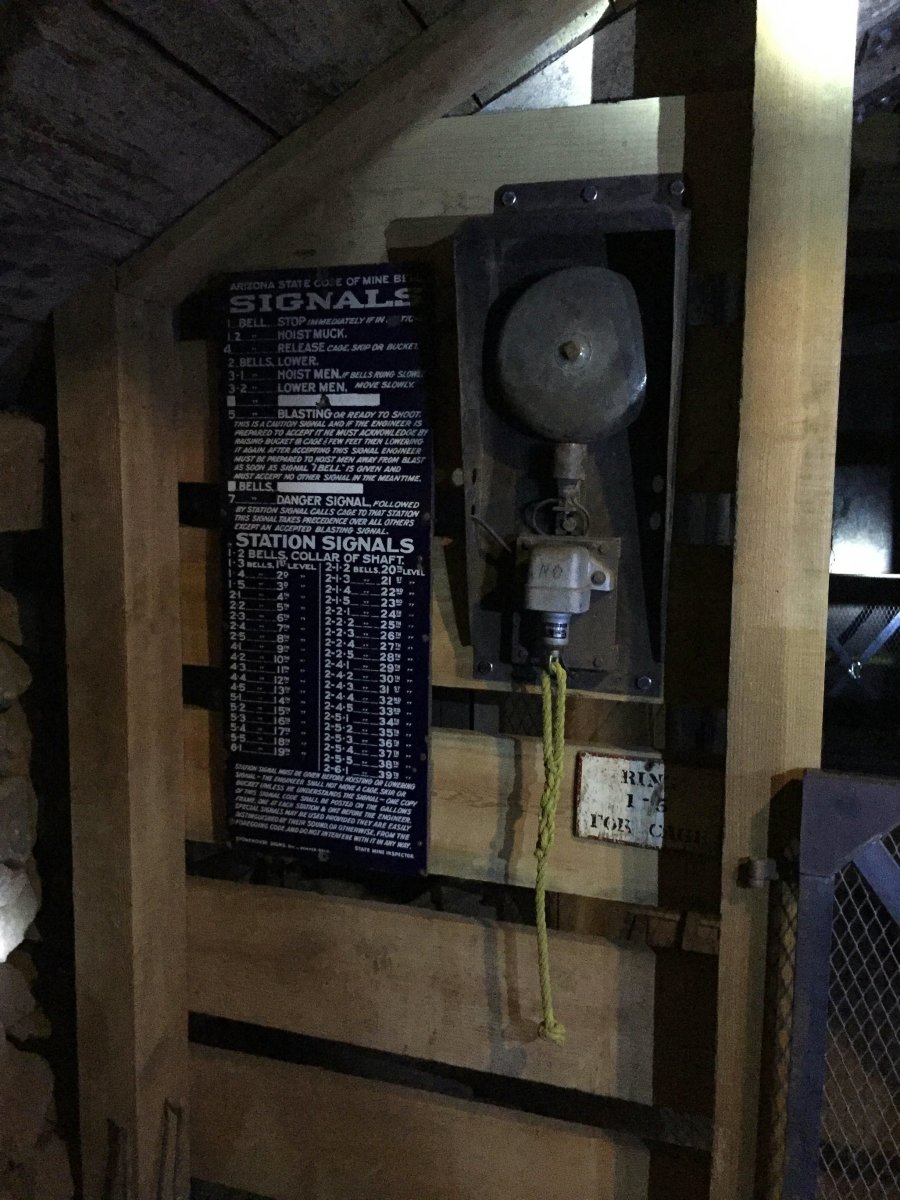

(Above) MHAer, Mike Canty (left), and Doug Graeme, Queen Mine Manager, are at the restored Level 3 Station of the Southwest Shaft which was used to reach deeper ore. (Right) Sturdy timbers support the rock surrounding the station. The shaft was used for hoisting ore in mine cars, lowering explosives and other supplies, and for transporting the miners in the cage.

|  |

A series of bell signals were used to communicate with the hoist operator on the surface. |

Early mine cages were open and afforded little protection for the miners. The enclosed sides and gates shown here greatly improved safety for the cage occupants. |

|  |

| (Above and left) On the mine tour, visitors can walk up a stairway into an actual large stope. The miners climbed ladders in narrow raises. Soft ore was mined by pick and shovel and, when necessary, by drilling and blasting. As ore was mined the stope grew larger in all directions following the irregular shape of the deposit. When the surrounding rock was unstable, the miners constructed timber square sets to support the walls of the stope. The square sets could be filled with waste rock for added support. Square set mining was a very costly mining method; however, the high percent of copper in the ore at the Copper Queen made this method practical. The Copper Queen Mine is famous for its spectacular array of different mineral specimens. A miner’s job was to remove every scrap of ore. Fortunately, many specimens never made it to the smelter and were preserved by collectors. The collection of James Douglas, President of the Copper Queen Consolidated Mining Company and later Phelps Dodge, was donated to the Smithsonian Institution in Washington, DC. Specimens from Douglas’ collection can also be seen in the Bisbee Mining and Historical Museum, a Smithsonian affiliate. |

One of the more curious things seen on the tour was this bicycle used by foremen to travel from one part of the mine level to another. |

Another curiosity is shown above. Even an underground mine the miners have to answer the call of nature. |